Plants Adapt their Lignin Using Chemical ‘Encoding’ Enzymes, New Report Suggests

Bio4Energy Associated Member Edouard Pesquet, previously with Umeå University, is part of a group of internationally leading scientists on fundamental research on the plant polymer lignin. Pesquet was part of the organisation team that started the international conference Lignin in 2014. Because of his experience with Bio4Energy at Umeå, Sweden and the support he gained during his time here—becoming a Gunnar Öquist Fellow—Pesquet has continued being part of, and publishing with, the Bio4Energy Research Environment.

Stockholm, 1 December 2022

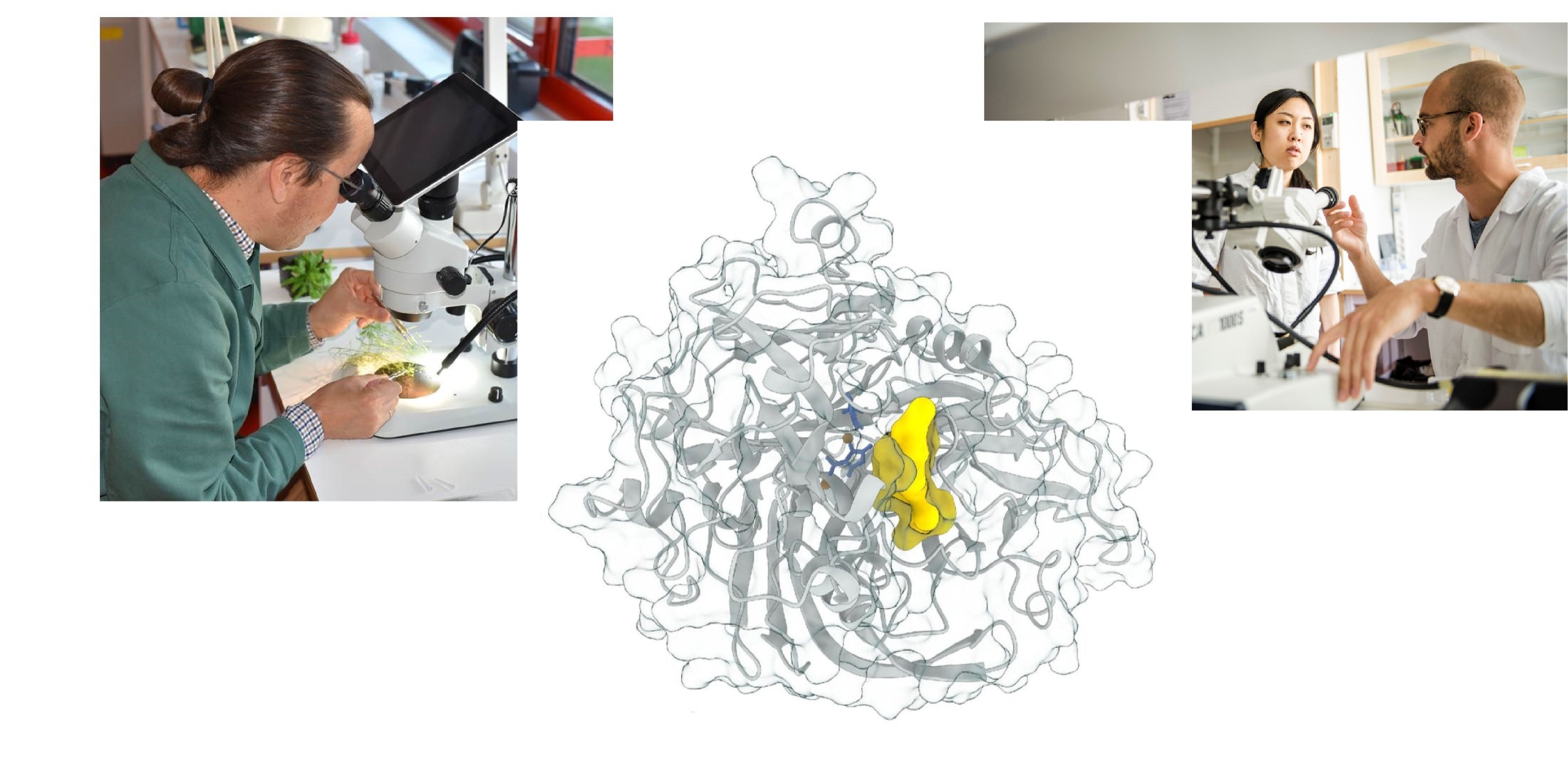

Plants “encode” specific chemistries of their lignin polymer substance to grow tall and be resilient. To do so, each plant cell uses different combinations of a specific type of enzyme, a new report suggests.

The results can be used both in agriculture and in forestry for selecting plants according to their chemistry, for them to resist altered conditions brought about by climate change, according to a press release from Stockholm University (SU).

The plant polymer lignin is an important carbon sink for the environment since it stores about one third of total carbon on the planet. It allows plants to hydrate and reach heights of up to 100 metres.

At the cell level, specific lignin chemistries adjust a plant’s mechanical strength to support growth and survival.

Bio4Energy scientists at SU recently demonstrated that lignin has a chemical “code” that is adapted at the cell level to fulfill different roles in plants. They way in which cells “encode” the lignin chemistry of a plant, however, remained unknown.

The researchers; led by Edouard Pesquet, associate professor in molecular plant physiology and senior author of the study; show that a type of enzymes called LACCASEs are used by each cell to adjust their lignin chemical “code”, in order to resist stresses such as drought or strong winds.

The study finally shows that lignin is spatially controlled at the nanometre level in each plant cell.

“The control of lignin chemistry at the cell level is ultimately the mechanism enabling plants to grow, hydrate and resist climate change stresses. These results finally demonstrate how lignin chemistry is controlled and open great possibilities to select plants upon their lignin ‘code’ to improve crops and trees’ resistance to water availability problems”, Pesquet said.

Text by Amanda Gonzalez Bengtsson, with editing by Anna Strom

Contact

Edouard Pesquet, Stockholm University — Bio4Energy Associated Member, Bio4Energy Forest-based Feedstocks and formerly with Umeå University and Umeå Plant Science Centre

Scientific article

Different combinations of laccase paralogs non-redundantly control the lignin amount and composition of specific cell types and cell wall layers in Arabidopsis, by Blaschek et al., is published in the journal The Plant Cell November 2022.

Stockholm University/Edouard Pesquet

Stockholm University/Edouard Pesquet ©AnnaStrom

©AnnaStrom LTU

LTU ©AnnaStrom

©AnnaStrom