New Projects Supported by Bio4Energy Strategic Funds

Twenty per cent of all funding to Bio4Energy is set aside as Strategic Funds used to create synergies, explore and address new and important avenues of research. In 2023, several such strategic projects will be launched, following a call for funding during the autumn. The first two projects started on 1 January 2023, with additional projects coming up later.

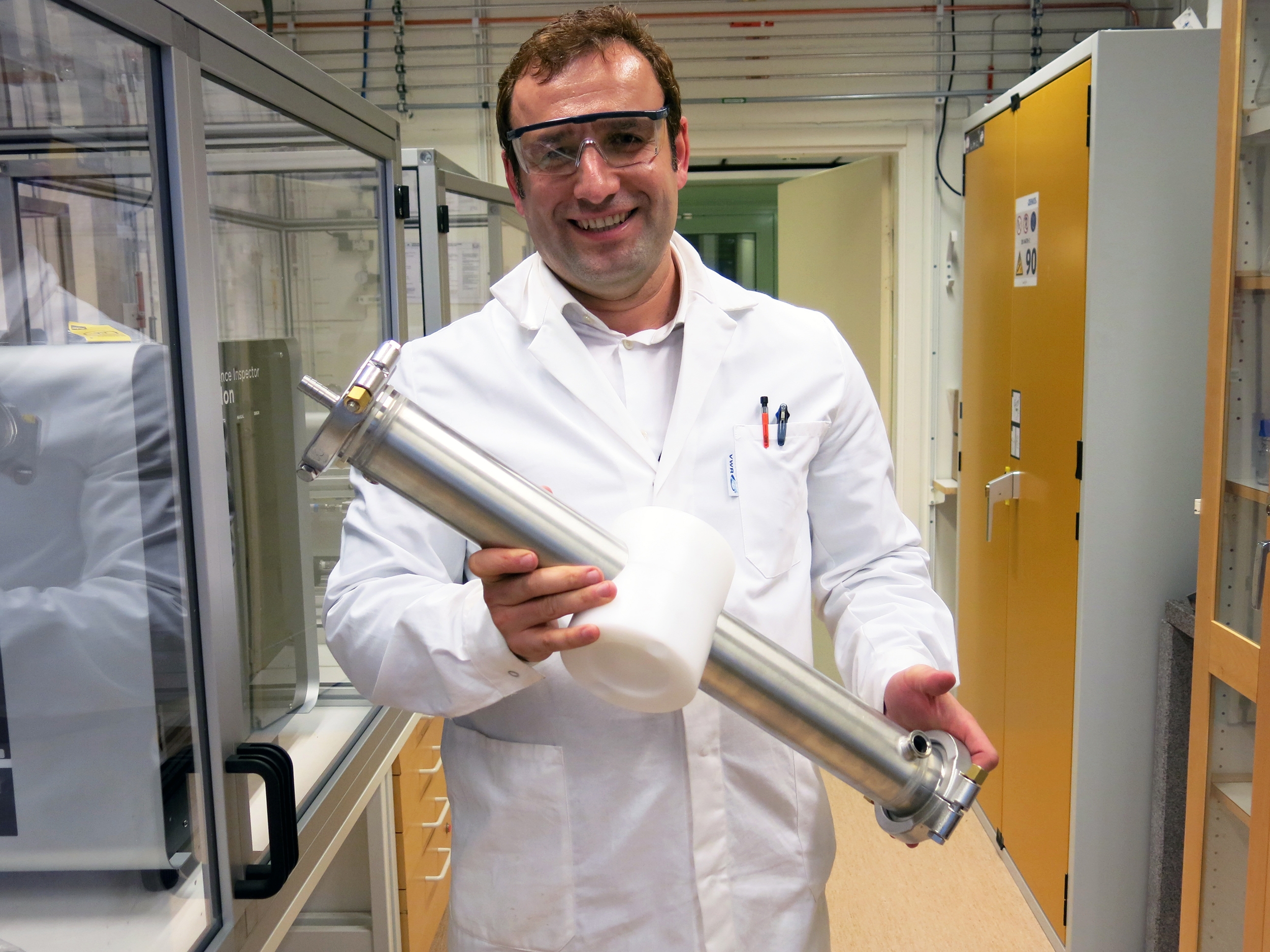

The project “Circular and sustainable production of bioplastics with the help of photosynthetic microorganisms – Proof of concept”, aims to investigate the feasibility of feeding carbohydrates produced by photosynthetic microalgae to bacteria producing polyhydroxybutyrate (PHB) at pilot scale in northern Sweden. PHB is a promising material for producing biodegradable plastics, and in this proof-of-concept project the PHB production will be studied and optimised, in order to enable a successful implementation at industrial scale. Francesco Gentili at SLU heads the project, which is a collaboration between researchers at SLU, UmU, and RISE Processum.

The second project, “Trade-off between wood quantity and quality in response to nitrogen fertilization – Is there a breaking point for beneficial nitrogen level in boreal forests?”, will investigate the relationship between volume growth and wood quality in response to nitrogen fertilization in both Norway spruce and aspen. The goal is to identify optimal fertilization regimes that balance between volume growth and wood quality of forest feedstocks in different locations in Sweden. This will pave the way for feedstock with beneficial qualitative properties, without compromising the growth of the trees, even in poor and abandoned soils. The project, which is led by Hannele Tuominen at SLU, is a collaboration between SLU, UmU and RISE. More information about Bio4Energy’s strategic funds and projects, including a list of ongoing and finalised projects, can be found under this link.

Text by the Bio4Energy programme managers and deputy programme manager

©AnnaStrom

©AnnaStrom ©AnnaStrom

©AnnaStrom ©AnnaStrom

©AnnaStrom ©AnnaStrom

©AnnaStrom Bio4Energy ©2022

Bio4Energy ©2022

Bio4Energy©2022

Bio4Energy©2022 ©AnnaStrom

©AnnaStrom