A research report—covering five years of investigations—shows that microalgae grown in cold and dark conditions may not only be made to thrive on their own, but also remove the heavy metal content of industrial wastewater that conventional treatment plants do not filter out.

The high performing algal strain selected also turned out to produce ample carbohydrate biomass suitable for making bio-based plastics.

The academic research team behind the findings is based in northern Sweden; where winters are long, cold and dark. However, the cluster—including the research environment Bio4Energy and the MicroBioRefine project—have some of Scandinavia’s leading scientists in the field of developing biomass from blue-green algae as a renewable input material for making products.

The research report, by recent PhD graduate Martin Plöhn, will be released by Bio4Energy’s lead partner Umeå University as soon as details of its major findings have been cleared for publication in the chief biotechnology journal of a well-known publisher.

The researchers have identified a common and locally available strain, Chlorella vulgaris, as a top performer among microalgae when it comes to cleaning wastewater of cadmium, copper and lead. There was no additional source of energy or lighting added.

In a nutshell, the researchers have identified a common and locally available strain, Chlorella vulgaris, as a top performer among microalgae when it comes to cleaning wastewater of cadmium, copper and lead. The process has been tested in a research laboratory. There was no additional source of energy or lighting added to indoor room temperatures, daytime indoor (fluorescent) lighting and natural daylight.

Cleaning with microalgae after conventional wastewater treatment, to meet legal standards

Turned into a fully-fledged technology, the scheme would allow industries whose activities leave substantial amounts of wastewater in their wake, to shave the last one-to-two micrograms of heavy metals off wastewater already treated in a conventional treatment plant. The scheme comes with optional provisions for reuse in industry of the heavy metals thus recycled.

“Our microalgae can be used to treat wastewater to remove pollutants and produce freshwater…. We do not want to replace the conventional treatment system, but come in at the end and take away the heavy metal content that is still higher than the law”, doctor Plöhn told Bio4Energy Communications.

“Our microalgae can be used to remove pollutants and treat wastewater to produce freshwater… We do not want to replace the conventional treatment system, but come in at the end and take away the heavy metal content that is still higher than the law”.

In the second part of the microalgae project, Chlorella vulgaris again outperformed other strains tested when it came to producing polyhydroxybutyrate (PHB), a type of plastic, via bacterial breakdown of the biomass. The process has been tested in up to 25 litres of wastewater at a time, in a research laboratory.

Checking for unwanted emissions and scaling up

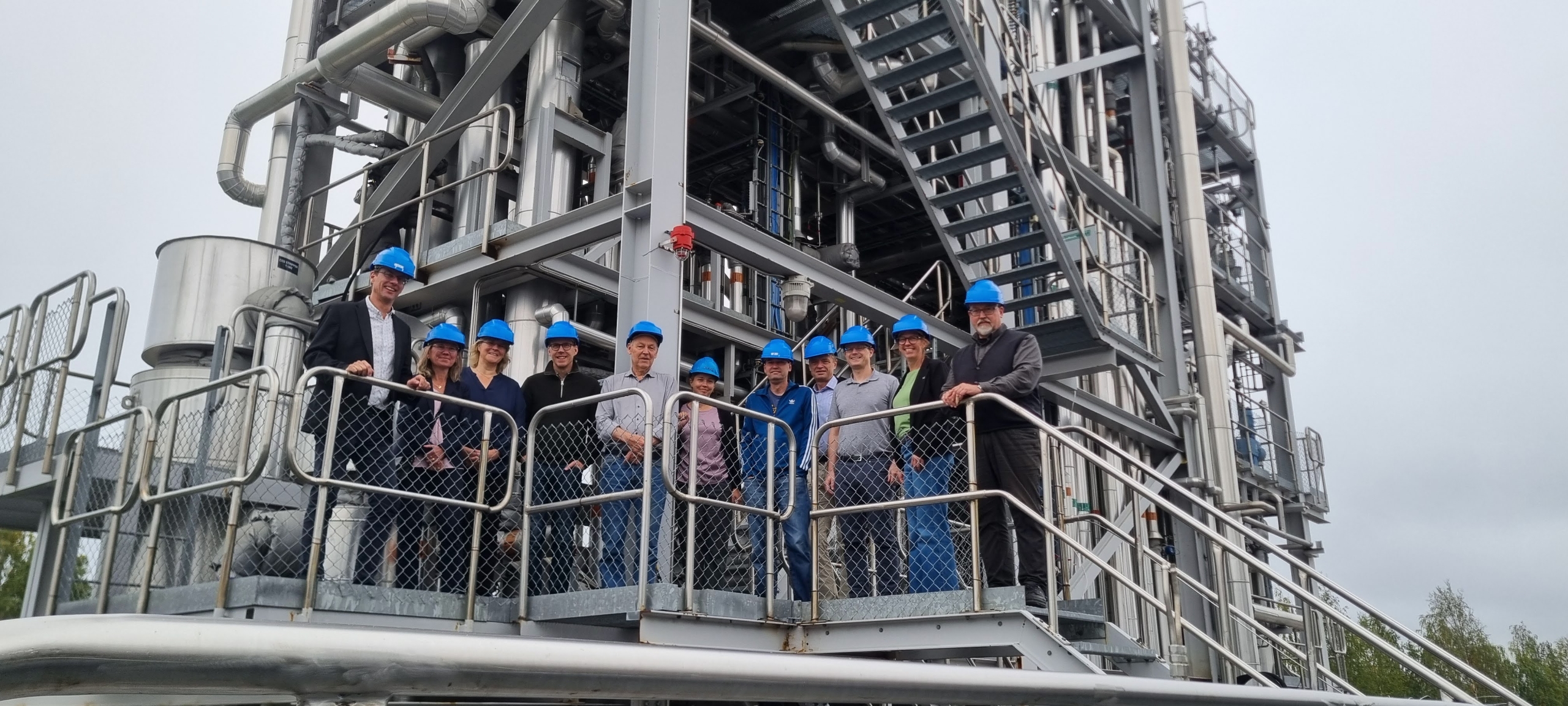

After successful proof of concept trials, the researchers have received expressions of interest for testing the concept on a larger scale from Bio4Energy partners at the RISE Research Institutes of Sweden. Plöhn and colleagues now are looking for industrial partners.

“We are looking for people who could be interested in the forest industry, with the message that we can add value… to existing processes”, he said.

The researchers collaborate with colleagues at the Swedish University of Agricultural Sciences to perform life-cycle assessment studies; to double check that their concept is sustainable in terms of minimising greenhouse gas emissions. Technically, the algae consume carbon dioxide down to net zero, but the researchers want to make sure that the system is water tight.

Dissertation in hand, Plöhn is not about to finish working on the project anytime soon. The microalgae also produce lipids and protein. Moreover there is the bio fertilizer route that remains to be explored.

“I see opportunities to explore this concept beyond carbohydrates. There will always be wastewater that needs to be treated. We need to use what we have right now”, he said.

Since late March Plöhn is a staff scientist at Umeå University and industry representatives are invited to contact him and the research team there for at least another nine months.

New for September 2024: News by NewsGram, Researchers aim to create biodegradable plastic – from algae (newsgram.com)

PhD Dissertation

Revealing the potential of Nordic microalgae — Turning waste streams into resources

Bio4Energy Contacts

Doctor Martin Plöhn — Affiliation with Umeå University

PhD Supervisor, Professor Christiane Funk — Affiliation with Umeå University

Related Projects

For more information

MicroBioRefine project

Bio4Energy Biopolymers and Biochemical Conversion

Irina Iakovleva

Irina Iakovleva

©AnnaStrom

©AnnaStrom RISE

RISE

©AnnaStrom

©AnnaStrom

Bio4Energy

Bio4Energy

AnnaStrom

AnnaStrom