Inventions by Bio4Energy Researchers Highlighted by Royal Academy for Future Potential

Zeolite membranes for gas separation, vertical gardens and reuse of textiles to make composites. These are subjects of collaboration projects by Bio4Energy researchers who have made this year’s 100 List hosted by the Royal Swedish Academy of Engineering Sciences (IVA).

To make the List, it takes a research project deemed to have “great potential to be useful”. This usefulness is thought of as potential for commercialisation of the product or concept studied, for development of either business or methods, or for providing thought leadership.

Another key criterion is for the project leader or researchers on the project to have expressed interest in collaborating with industry or related entities to further develop their invention.

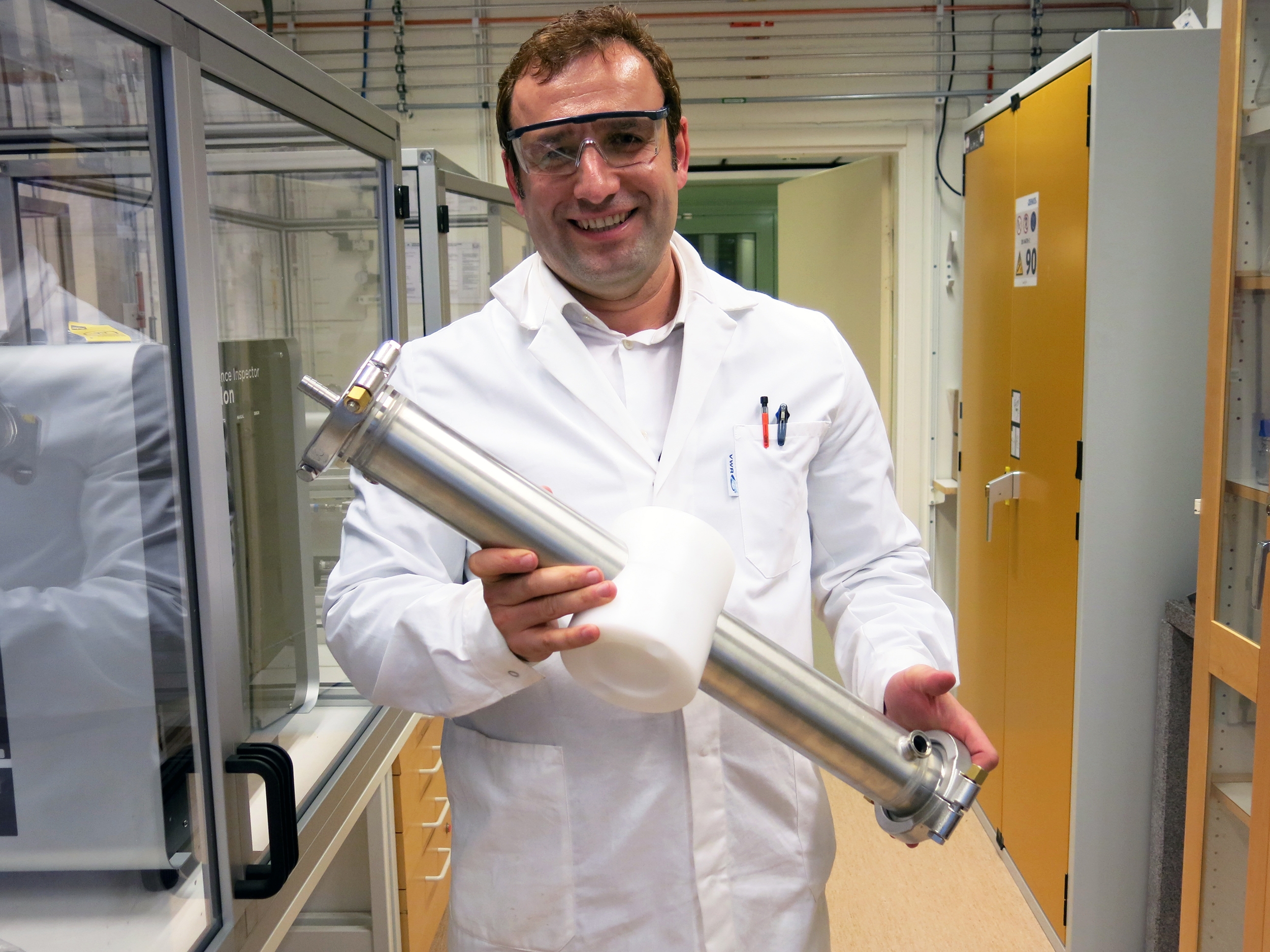

Membrane technology for gas separation in use, tends to be bulky, energy intensive and cost a lot. Bio4Energy researchers Jonas Hedlund and Liang Yu are perfecting and developing ultra-thin zeolite membranes that take up less space and use less energy to perform the separation. These membranes would provide a large cost reduction if rolled out on a large scale, according to the scientists.

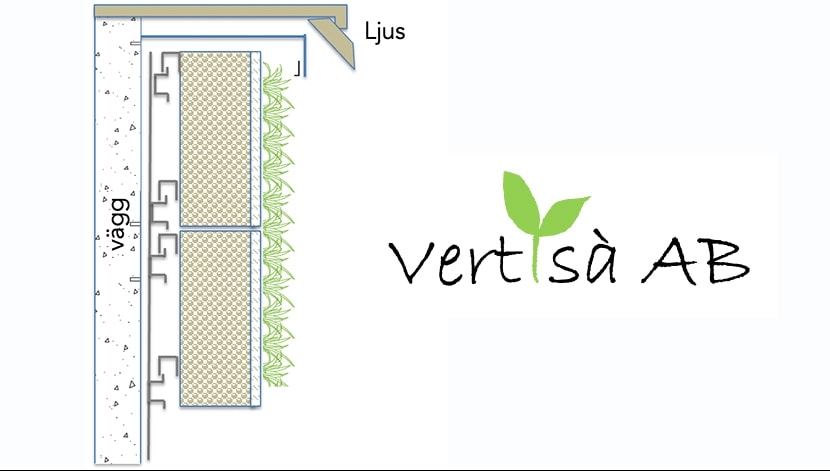

With Vertisà Ltd, Rosario García-Gil and team propose a module vertical garden that can be added onto the exterior of a house and mimics a natural ecosystem. Complete with a built-in watering system, which has been patented, it is not only designed to help with greenhouse gas capture in cities, but also serves to insulate and beautify the wall it is attached to. The module is both low-technology and low cost, according to the project leader.

A new process has been invented, which allows for reuse of scrapped textiles as a component in a new, strong type of composite material based on a mixture of discarded textiles and plastics. Kristiina Oksman and co-workers used a piece of process equipment called extruder, to mix the cut fabrics with plastics. The resulting composite is two fifths textiles and costs less than the standalone plastic polymer.

Contacts

Jonas Hedlund and Liang Yu, Bio4Energy Catalysis and Separation, affiliation with Luleå University of Technology

Rosario García-Gil, Bio4Energy Forest-based Feedstocks, affiliation with the Swedish University of Agricultural Sciences

Kristiina Oksman, Bio4Energy Biopolymers and Biochemical Conversion, affiliation with Luleå University of Technology

LTU

LTU ©AnnaStrom

©AnnaStrom Bio4Energy©2022

Bio4Energy©2022