Utilising the natural composition of industrial bio-based residues for efficient separation of functional nanofibers

Project leader: Linn Berglund, linn.berglund@ltu.se

Other participants: Io Antonopoulou, Carlos Martín, Ola Sundman, Shaojun Xiong

Platforms: BioPolChem, FeedPro

Organisations: LTU, UmU, SLU

Status: Completed

Reference: B4E3-TM-1-03

Call: B4E3-TM-1, 2021

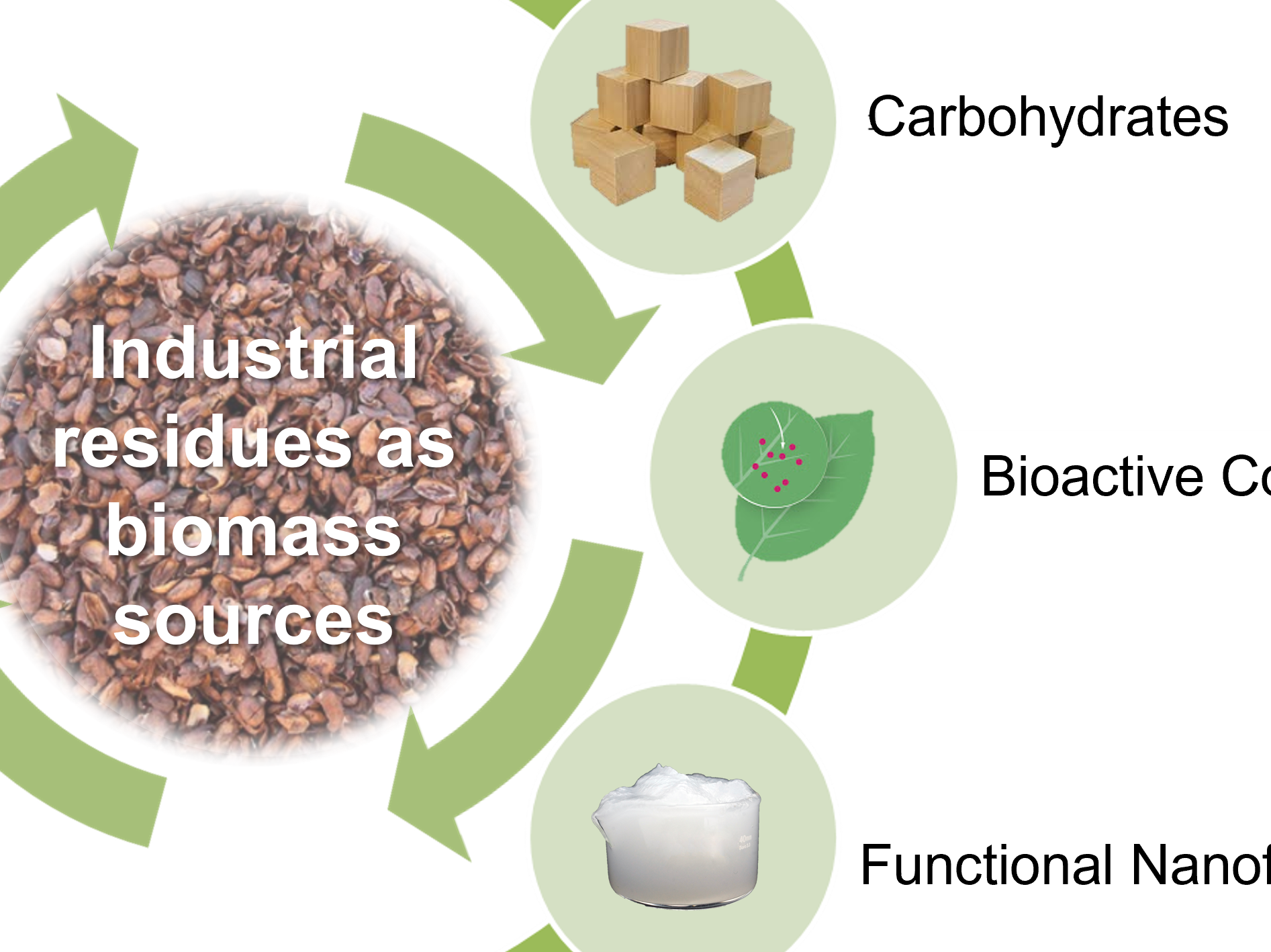

The main aim of this project was to separate functional nanofibers from bio-based residues by using their natural composition for increased resource efficiency combined with the development of nanofibers with specific functionality. Within a biorefinery perspective, exploiting cellulosic biomass, from industrial residues is advantageous both from an environmental and economic point of view. This applies to the entire chain of resources, from sustainable use of raw materials to the reduction of residues by means of waste treatment or disposal and furthermore to the development of high value-added products.

Residues from food industry were evaluated for nanofiber production potential targeting high yield and efficient processing. A commercial birch kraft pulp was used as a reference material in this project, since nanofiber production is today most commonly done from wood pulp. Overall, the bio-residues could be successfully processed into functional nanofibers with at a lower energy demand compared to the reference material.

The nanofibers have potential uses in applications such as packaging and biomedical, and/or as reinforcements in bionanocomposites. The project has demonstrated how nanofibers with specific functionality can be sustainably produced from industrial bio-residues and thereby contribute to added-value of these residues, as well as promote resource-efficiency described as a global goal for a more sustainable development in Agenda 2030.

Keywords: natural resources; bio-residues; efficient processing; nanocellulose; sustainability

Courtesy Linn Berglund, Bio4Energy

Courtesy Linn Berglund, Bio4Energy

Bio4Energy

Bio4Energy ©AnnaStrom

©AnnaStrom