Bioethylene purification through energy efficient technology

Project leader: Naser Tavajohi, naser.tavajohi@umu.se

Other participants: Liang Yu, Jyri-Pekka Mikkola

Platforms: CatSep

Organisations: UmU, LTU

Status: Completed

Reference: B4E3-TM-1-01

Strategic call: B4E3-TM-1, 2021

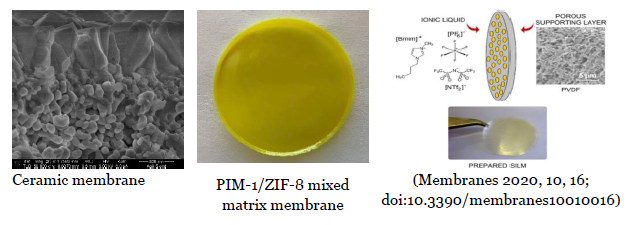

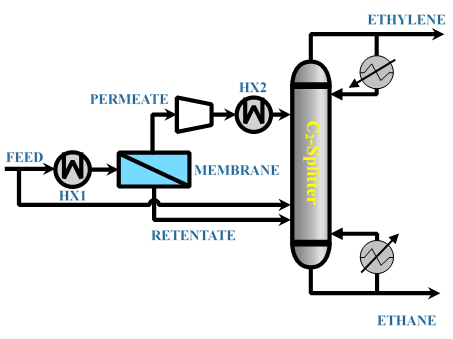

The production of bioethanol from lignocellulosic biomass has huge potential in future as it does not compete with food chain supply and required less land and water for their reproduction. Yet, the product stream of crude bioethylene comprises a range of other by-products such as methane, ethane, propane, propylene, butane, higher hydrocarbons, carbon monoxide, carbon dioxide and water (steam). To achieve the polymer-grade purity of ethylene, the current bioethylene production plants still are using traditional energy-intensive purification processes (cryogenic distillation). Membrane and absorption processes may enable energy lean purification of ethylene as compared to cryogenic distillation. In the proposed project, we developed and assessed three types of membrane materials that are suitable for the purification of bioethylene to polymer grade purity at low energy consumption. Type-1 ceramic membranes, Type-2 Mixed Matrix Membranes, and Type-3 silver-based supported ionic liquid membranes.

Keywords: bioethylene; membrane separation; cryogenic distillation; gas separation; olefins

Bio4Energy 2022

Bio4Energy 2022

Bio4Energy

Bio4Energy